Offshore wind farms are growing rapidly as a source of clean energy, with massive turbines standing tall in the open sea to capture strong winds. Maintaining these turbines requires skilled technicians to visit them regularly for checks and repairs. This is where the SOV vessel comes in—a service operation vessel designed to act as a floating home and base for these workers. One of the smartest features on a modern SOV vessel is walk-to-work technology, which allows people to step safely from the ship onto a turbine platform. Imagine crossing a steady bridge over moving water, no matter how wavy the sea gets. Walk-to-work technology on SOV vessels makes this possible through clever systems that counteract the ocean’s motion. It’s a game-changer for safety and efficiency in offshore wind operations. In this simple explanation, we’ll break down how it works, why it’s important, and what makes it so effective for non-technical readers curious about renewable energy at sea.

What Is an SOV Vessel?

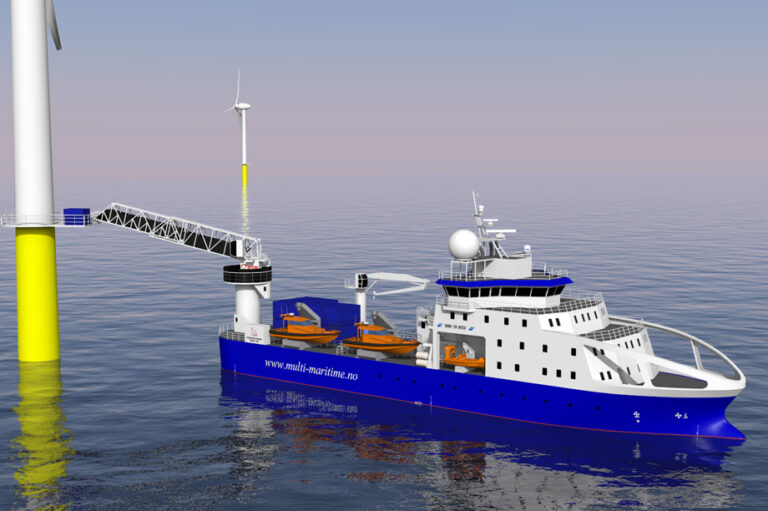

An SOV vessel is a specialized ship built to support offshore wind farms over long periods. Unlike smaller boats that shuttle workers back and forth from shore each day, an SOV vessel stays out at sea for weeks, providing comfortable living quarters, workshops, and storage for tools and parts. It carries a team of technicians who live on board, eating, sleeping, and relaxing there between shifts.

The SOV vessel is stable and equipped with powerful engines to hold its position near turbines, even in challenging weather. It often includes small boats for quick trips and cranes for lifting equipment. But the star feature for many is the walk-to-work system, which turns the SOV vessel into a reliable mobile workstation. This setup reduces travel time and fatigue for workers, allowing more focus on fixing turbines and keeping the wind farm producing power steadily.

Understanding Walk-to-Work Technology

Walk-to-work technology refers to a special bridge-like structure, called a gangway, mounted on the SOV vessel. This gangway extends out to connect directly to the landing platform on a wind turbine. Workers can simply walk across it, carrying tools or pushing carts, without needing to climb ladders or jump between moving objects.

In the past, getting to turbines involved risky methods like climbing from bouncing boats or being lifted in baskets. Walk-to-work on an SOV vessel changes that by creating a safe, steady pathway. The gangway is long enough to reach from the ship to the turbine and adjustable in height to match different platform levels. It’s often enclosed or protected to shield workers from wind and spray, making the crossing feel more like stepping onto a docked ferry than braving the open ocean.

How Motion Compensation Works Simply

The real magic of walk-to-work technology on SOV vessels is motion compensation. The sea is rarely calm, so both the ship and turbine move with waves—up and down, side to side, and back and forth. Without compensation, the gangway would bounce wildly, making it dangerous to cross.

Motion compensation uses smart sensors and hydraulic systems to keep the gangway’s tip steady on the turbine platform. Sensors constantly measure the ship’s movements in real time. A computer then sends signals to actuators—like powerful cylinders—that adjust the gangway instantly. If the ship rises on a wave, the gangway extends or angles down to stay level. If it rolls sideways, the system counters that roll.

There are active and passive parts to this. Active compensation uses power to make precise adjustments, while passive elements absorb smaller shocks like cushions. Together, they handle waves up to several meters high, far beyond what was safe before. The result is a gangway that feels almost still at the connection point, allowing confident walks even when the ocean is rough.

Components of a Walk-to-Work Gangway

A typical walk-to-work gangway on an SOV vessel has several key parts working together. The base is a strong pedestal fixed to the ship’s deck, providing a solid foundation. From there, the main bridge section extends outward, often telescoping to change length as needed.

Hydraulic cylinders control the angle and height, similar to how a crane arm moves. At the tip, there’s a docking mechanism that grips the turbine platform gently but firmly. Some systems include a tower to lift the gangway higher for taller turbines.

Many gangways double as small cranes, lifting cargo alongside people. Controls are simple, operated from a panel on the SOV vessel, with safety overrides to retract quickly if needed. These components are built tough from lightweight materials to withstand salt and storms, ensuring reliable use day after day.

Benefits for Safety and Operations

Walk-to-work technology greatly improves safety on SOV vessels. By providing a stable path, it reduces slips, falls, and strains that come with older transfer methods. Workers arrive fresher and less stressed, ready to focus on technical tasks high up on turbines.

Operationally, it extends working days. An SOV vessel with this technology can operate in higher waves, meaning fewer cancellations due to weather. This keeps wind farms running smoothly, producing more energy overall. It also lowers costs by reducing helicopter use or extra boat trips. For the environment, fewer disruptions mean steadier green power output.

Crews appreciate the comfort—crossing feels routine, not adventurous. Overall, walk-to-work on SOV vessels supports the growth of offshore wind by making maintenance practical and predictable.

Challenges and Limitations

No technology is perfect, and walk-to-work systems on SOV vessels have limits. They work best within certain wave heights—usually up to around three meters of significant waves. Beyond that, operations pause for safety.

The gangway needs precise positioning of the SOV vessel, relying on its dynamic positioning thrusters to stay close without colliding. Maintenance of the system itself is important, as hydraulics and sensors require checks. In very extreme conditions or with very large turbines, additional adaptations might be needed.

Still, ongoing improvements address these, making the technology more robust over time.

The Future of Walk-to-Work on SOV Vessels

As offshore wind farms expand to farther and deeper sites, walk-to-work technology on SOV vessels will keep advancing. Future gangways might handle even taller turbines or rougher seas with better compensation. Integration with smarter ship controls could automate more of the process.

Eco-friendly features, like electric-powered adjustments, fit the renewable theme. Some designs explore combined cargo and people flow for greater efficiency. The trend points toward more reliable, year-round access, helping offshore wind meet rising energy needs sustainably.

FAQs

What is walk-to-work technology on an SOV vessel?

It’s a compensated gangway that connects the SOV vessel to a wind turbine, allowing workers to walk across safely.

How does motion compensation make transfers safe?

Sensors detect ship movement, and hydraulic systems adjust the gangway to keep the end steady on the turbine platform.

Can walk-to-work be used in bad weather?

Yes, it works in moderate waves, extending safe operating windows compared to traditional methods.

What happens if waves get too big?

Operations stop, and the gangway retracts for safety, as the system has built-in limits.

Do all SOV vessels have walk-to-work technology?

Many modern ones do, as it’s becoming a standard feature for efficient offshore wind support.

How long is a typical gangway on an SOV vessel?

It can extend far enough to bridge the gap, often adjustable to suit different turbine distances.

Final Words

In the story of offshore wind energy, walk-to-work technology on SOV vessels is a quiet but powerful chapter. It turns the unpredictable ocean into a manageable workplace, empowering teams to harness renewable power with confidence. As this technology evolves, it promises even greater strides in safety and sustainability, reminding us how smart solutions can make big dreams—like endless clean energy—a practical reality. Whether you’re new to the topic or deeply interested, appreciating this innovation highlights the thoughtful engineering behind our greener future.

Comments are closed.